Production Processes

Raw Material Reception

The fruit arrives fresh, directly from local producers' fields. The first check is done here, verifying that the truck arrives in the required conditions, and the quality of the fruit is optimal.

0°C Chamber

The pallets are entered into a chamber with an ambient temperature between 0°C and 8°C.

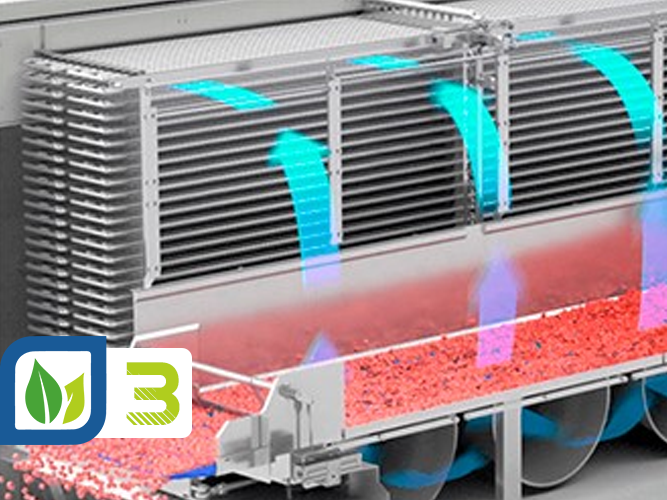

Static Tunnel / Continuous Tunnel

The product passes through a tunnel that takes it to a temperature of -18°C, working with freezing temperatures between -21°C and -25°C. The continuous tunnel's capacity is up to 2000 kg of frozen product per hour.

Freezing Chamber

To homogenize the product's temperature, it enters a chamber maintained at -18°C, thus avoiding fruit breakage.

Processing Room

The good fruit is selected, eliminating any with defects. A second quality control separates the finished product from what is considered subproduct.

Packaging

Sealing and Labeling

Each box is identified with labels that provide necessary information about the product, such as the type of fruit, production date, box code, etc.

Metal Detector

It is checked that there is no metal presence within the packaged fruit or in the packaging material. The product that does not pass these controls will be set aside, reviewed, and tested again.